Reynolds Services, Inc. is excited to announce that its metal coating and decorating subsidiary, RSI Metal Litho Greenville, has acquired the first Koenig & Bauer MetJET ONE, the First Digital Printing Press in a Production Line for Metal Decorating. Benefits of this system include outstanding digital print quality, appealing price-performance ratio, and modular and customizable line configuration. Contact RSI Sales to place an order for our field test or for more information on this revolutionary product. Stay tuned for more news on this exciting development.

Koenig & Bauer has successfully developed the first digital printing press that is integrated into a production line for metal decorating. As a leading supplier in the field of metal decorating, the Group subsidiary Koenig & Bauer MetalPrint thus enables a simple and flexible entry into the world of digital printing. The machine will start a field test at the beginning of 2025 in cooperation with Reynolds Services, Inc.

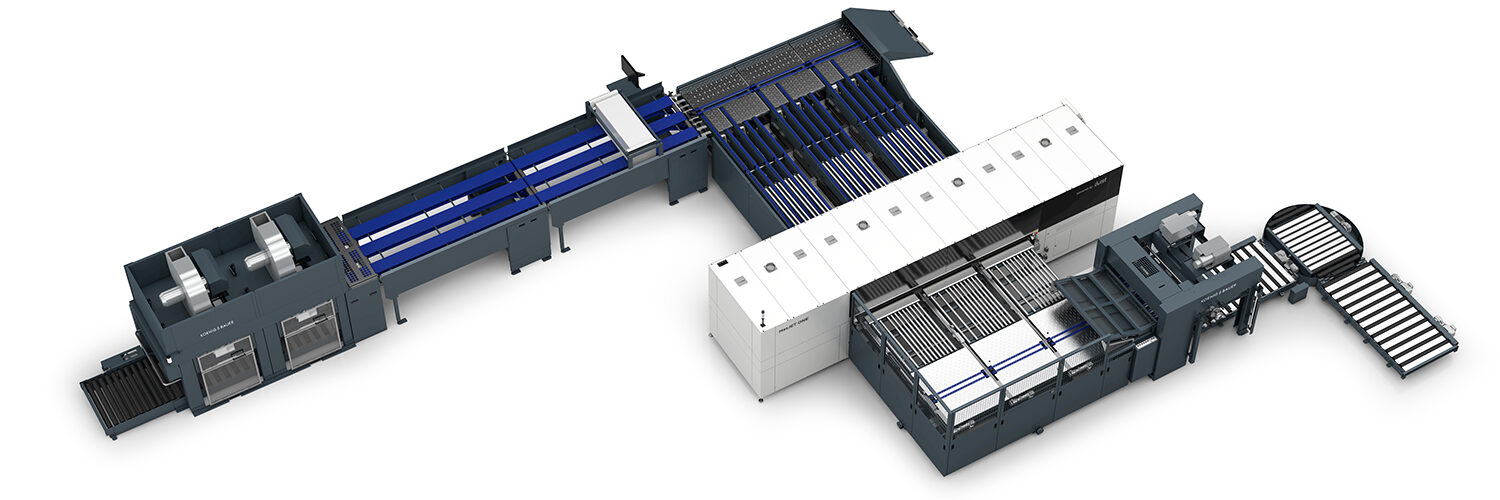

The basis of the MetJET ONE combines proven components from digital printing as well as sheet handling and system engineering for metal decoration: The sheet handling system is made by Koenig & Bauer MetalPrint, an expert in this field, while the integrated inkjet technology is based on a multi-pass printing unit from Durst, one of the leading players in the digital printing industry.

‘The MetJET ONE makes it as easy as possible for our customers to enter the world of digitally printed metal packaging,” explains Samuel Teufel, Product Manager at Koenig & Bauer MetalPrint. “The unique design enables us to create a customised solution that fits the flexibility and print quality requirements of our customers in the metal packaging industry.’

Thanks to the very attractive price-performance ratio and outstanding print quality, the standards in metal decoration are being redefined. The modularity of the MetJET ONE enables flexible customization and design of the entire production line to meet the demands of the packaging industry.

This means that the line can be equipped with the entire Koenig & Bauer MetalPrint portfolio in addition to the basic units. The MetalCoat coating machine, the inspection transport for checking the image (and overprint varnish) and the sheet management systems for reliable sheet ejection are just some of the possible features with which efficiency and profitability can be maximised on the MetJET ONE.

The field test, which will start early next year at RSI, is a crucial step in validating the machine’s performance and reliability under real operating conditions.

‘We are delighted to be working with Koenig & Bauer MetalPrint on the new MetJET ONE. We are convinced that this digital printing solution will enable us to realize customized prints in very short runs,” explains John Frangakis, CEO at Reynolds Services, Inc.